PVC Panel Production Line

Product Application

(1) PE panel

PE panel is widely used in electric power, chemical industries and machinery. Having advantages of low temperature resistance, good electrical insulation. With properties of non-toxic and harmless of the panel is that it would not do harm to human beings.

(2) PP panel

PP panel can be applied to environmental protection equipment, exhaust gas emission equipment, and acid and alkali resistance equipment. Better heating resistance, small density, non-toxic and tasteless characteristic make excellent product.

(3) PE aluminum plastic composite panel

PE aluminum plastic composite panel can be used as building exterior wall panel, interior decoration panel, ceiling, exterior wall decoration, balcony, indoor compartment,etc. It is good at having a better plasticization and maintenance, strong impact and high weather resistance.

Technical Highlights

● Guangdong Blesson Precision Machinery Co., Ltd. produces PVC panel production line, which is composed of parallel twin screw extruder, professionally designed extrusion die, calibration table with fast cooling and forming, haul off unit and cutting unit. Due to the excellent comprehensive performance it has, which makes the whole production line high efficient and energy-saving.

● We can also customize PVC panel production line according to physical samples or drawings.

Extruder:

● Our PVC panel production line can be equipped with parallel twin screw extruder. The screw design of parallel twin screw extruder can improve the overall plasticizing performance through professional optimization and superb alloy steel material with precise machining.

● Our parallel twin screw extruder adopts high -standard electrical components which helps to precisely control the operation and protect the extruder under different circumstances.

● Our PVC panel production can also be equipped with the conical twin screw extruder.

Extrusion die:

● The corrosion resistance of the surface of PVC panel extrusion die has been improved by chrome plating and polishing treatment, which can surely improve production efficiency and prolong the service life.

Calibration table:

● Our PVC calibration table has three-dimensional adjustment function, which is convenient for users to control the operation easily.

● Multiple vacuum joints and water joints of the calibration table can guarantee remarkable cooling and forming for different structure of PVC panel.

● Calibration table is made of stainless steel 304, which is elegent, durable, and reliable.

● With high efficient air drying device.

● The energy-efficient vacuum pump and water pump are from international brands, which have better corrosion resistance and performance.

Haul off unit:

● By using the type of pneumatic clamping, the clamping force of PVC haul off unit is adjustable according to the actual size of PVC panel.In addition, the pressure of reducing valve has auxiliary effect to pneumatic clamping.

● According to the actual demand of customers, our PVC panel haul off unit can be equipped with up and down laminating device.

Cutting unit:

● Our PVC panel cutting unit adopts high quality encoder to calculate the length in order to ensure accurate measurement and minimize the tolerance.

● The speed of our PVC panel cutting unit and haul off unit are synchronous with pneumatic reset function.

● PVC panel cutting unit is equipped with strong suction device for collecting the dust, which can effectively reduce the environmental pollution of workshop and protecting the cutting chamber system, as well as prolong the service life of the machine.

Product Model List

|

Model |

Size Range (mm) |

Extruder Model |

Max Output (kg/h) |

Length Of Production Line (m) |

Total Installation Power (kw) |

|

BLX-650PVC |

650X35 |

BLE65-132 |

280 |

28 |

130 |

|

BLX-850PVC |

850X35 |

BLE80-156 |

450 |

25 |

185 |

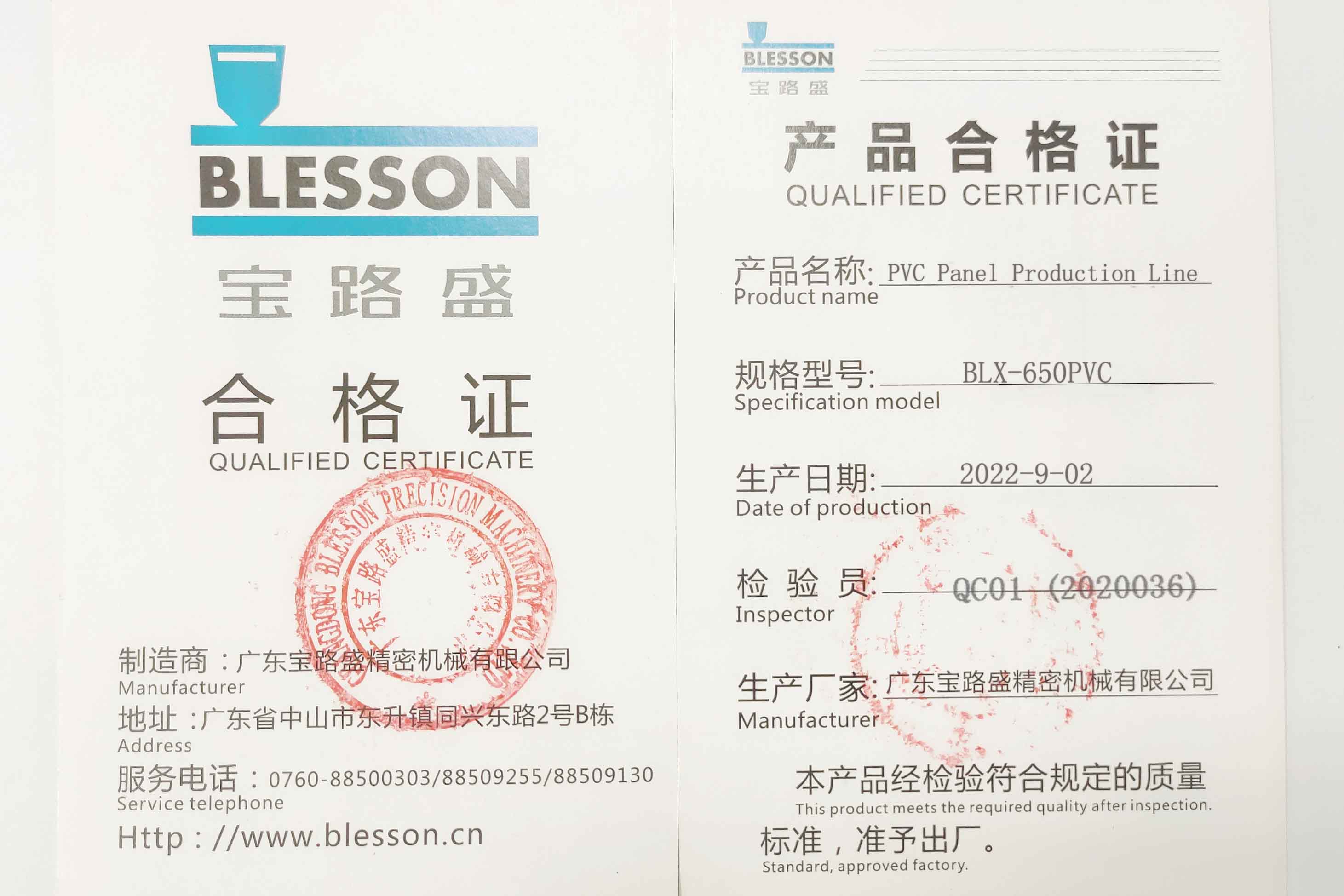

Warranty, Certificate Of Conformity

Guangdong Blesson Precision Machinery Co., Ltd. provides a one-year warranty service. During the use of the product, if you have any questions about the product, you can directly contact us for professional after-sales services.

Guangdong Blesson Precision Machinery Co., Ltd. provides product qualification certificates for each product sold, ensuring that each product has been inspected by professional technicians and debuggers.

Company Profile