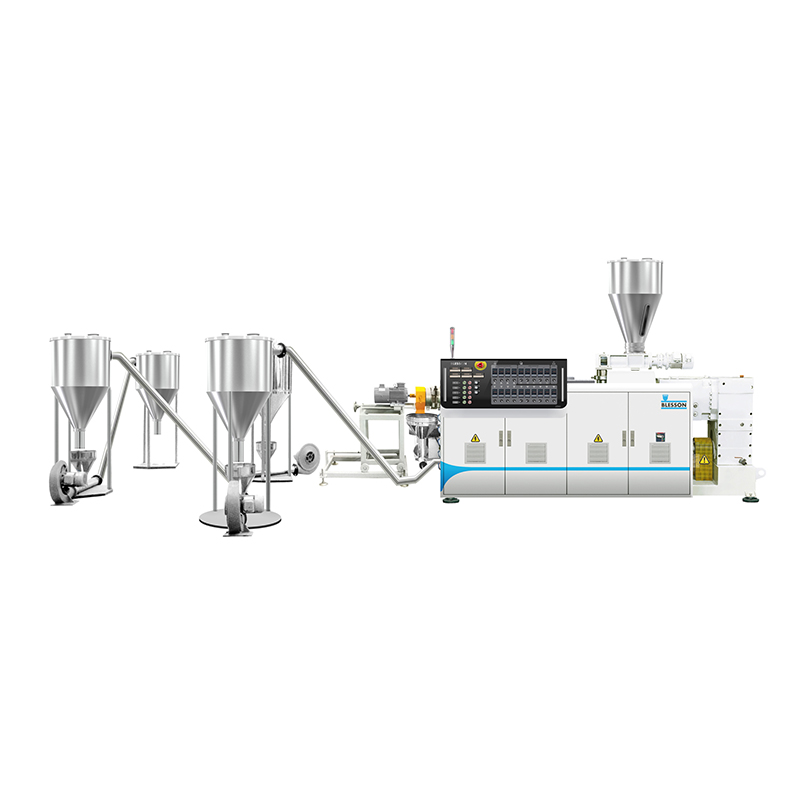

High Quality Plastic Pelletizing Line

Main technical features

1. The production line is composed of an extruder, pelletizing die, granulator, and cooling device, which is simply structured, and convenient to operate.

2. Conical twin-screw extruder with unique screw design, high output, and good plasticizing effect.

3. Unique die design for better molding effect.

4. The granulator cuts evenly, with a protective cover to ensure safe operation.

5. The granulation air tank is composed of two cooling tanks and one storage air tank, which is convenient and efficient for collection.

Model List

| Line Model | Cutting type | Extruder Model | Max. Output(kg/h) | Total Installation Power(kW) |

| BLZ-65PVC(I) | hot cut | BLE65-132G | 450 | 90 |

| BLZ-80PVC(I) | hot cut | BLE80-156 | 450 | 120 |

| BLZ-92PVC | hot cut | BLE92-188 | 850 | 200 |

| BLZ-95PVC | hot cut | BLE95-191 | 1050 | 220 |

| BLZ-130PVC(I) | hot cut | BLP130-26 | 1100 | 230 |

| BLZ-55PVC | hot cut | BLE55-110 | 180 | 76 |

| BLZ-65PVC(II) | hot cut | BLE65-132 | 300 | 90 |

| BLZ-65 PE/PPR | hob cold cut | BLD65-34 | 150 | 120 |

| BLZ-65 PE/PP | water ring hot cut | BLE65-132 | 150 | 120 |

| BLZ-75PET | hob cold cut | BLP75-40 | 350 | 190 |

| BLZ-80PE/PPR(I) | hob cold cut | BLD80-34 | 350 | 205 |

| BLZ-80PE/PPR(II) | hob cold cut | BLD80-34 | 350 | 180 |

| BLZ-80PVC(II) | hot cut | BLE80-156 | 450 | 170 |

| BLZ-80PVC(III) | hot cut | BLE80-156 | 450 | 170 |

| BLZ-80PVC(IIII) | hot cut | BLE80-156 | 450 | 170 |

| BLZ-92PVC(II) | hot cut | BLE92-188 | 850 | 215 |

| BLZ-92PVC(III) | hot cut | BLE92-188 | 850 | 205 |

| BLZ-95PET | hob cold cut | BLP95-40 | 650 | 340 |

| BLZ-130PVC(II) | hot cut | BLP130-26 | 1100 | 240 |

| BLZ-130PVC(III) | hot cut | BLP130-26 | 1100 | 240 |

| BLZ-150PE | hob cold cut | BLD150-24 | 280 | 340 |

Leave Your Message

Write your message here and send it to us