High-output PVC Twin Pipe Production Line 2-strand Pipe Extrusion Machine

Product Applications

The PVC twin-pipe production line from Guangdong Blesson Precision Machinery Co., Ltd. can produce PVC conduit, PVC drainage pipe, CPVC hot water pipe, PVC water pressure pipe, etc.

PVC conduit has the characteristics of high flame retardancy performance with excellent tensile and impact strength, which is suitable for telecommunications, transportation, urban construction and other fields.

PVC drainage pipes are widely used in indoor and outdoor drainage pipeline projects in buildings. Not only the linear expansion ratio of the pipe is low, but the deformation affected by temperature is also limited.

Environmental CPVC hot and cold drinking water pipes have excellent performance of high strength, good heat resistance. The highest operating temperature can reach 95°.

Technical Highlights

Blesson PVC twin pipe production line

● High-efficiency Conical Twin-Screw Extruder/Parallel Twin-Screw Extruder:

The PVC twin-pipe production line manufactured by Guangdong Blesson Precision Machinery Co., Ltd. is equipped with energy-saving conical twin screw extruder or parallel twin screw extruder. To guarantee the advanced mixing and plasticizing effect, our twin screw extruder adopts reasonable screw design with low shear rate to avoid the sensitive PVC material being decomposed easily.

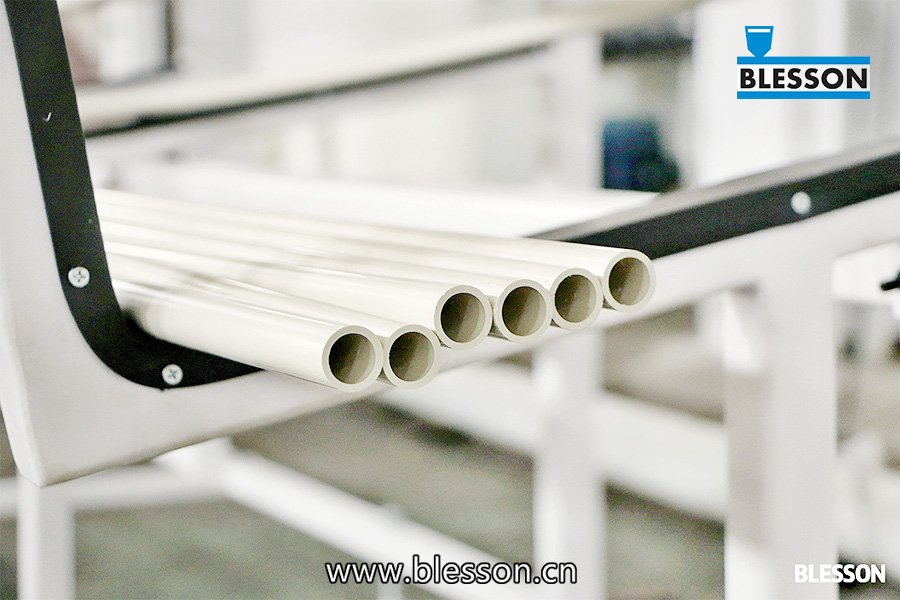

● PVC Twin Pipe Production Line 2-strand PVC Pipe Extrusion Die:

1. The die head of the PVC twin-pipe production line of Guangdong Blesson Precision Machinery Co., Ltd. adopts advanced bracket structure design.

2. The streamlined design of the flow channel ensures that the material can fully fill the flow channel and can be evenly extruded, at the same time avoid decomposition of the PVC material from overheating.

3. By replacing the bush, pin and calibrator sleeve of the PVC twin-pipe extrusion die, customers can quickly switch the production to different sizes of pipe.

4. The twin-pipe extrusion die of Blesson PVC twin-pipe production line adopts high-quality steel especially for mould. After polishing, hardening, and nitriding treatment, the durability of our twin-pipe extrusion die is effectively enhanced.

5. The 2 strand PVC twin pipe production line is more efficient than the ordinary one strand production line, which can effectively save production energy consumption, reduce land cost, and overcome the difficulty of low gross profit for small pipes.

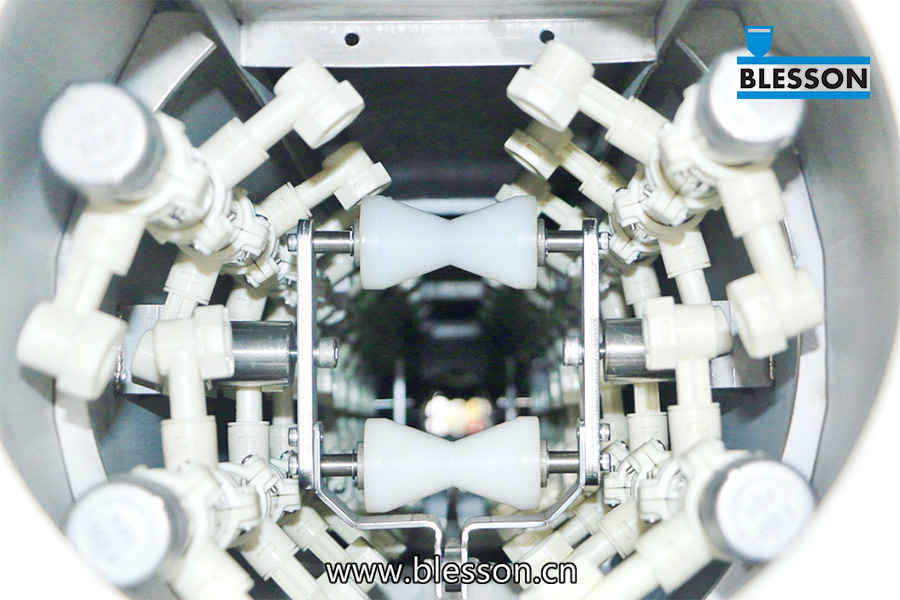

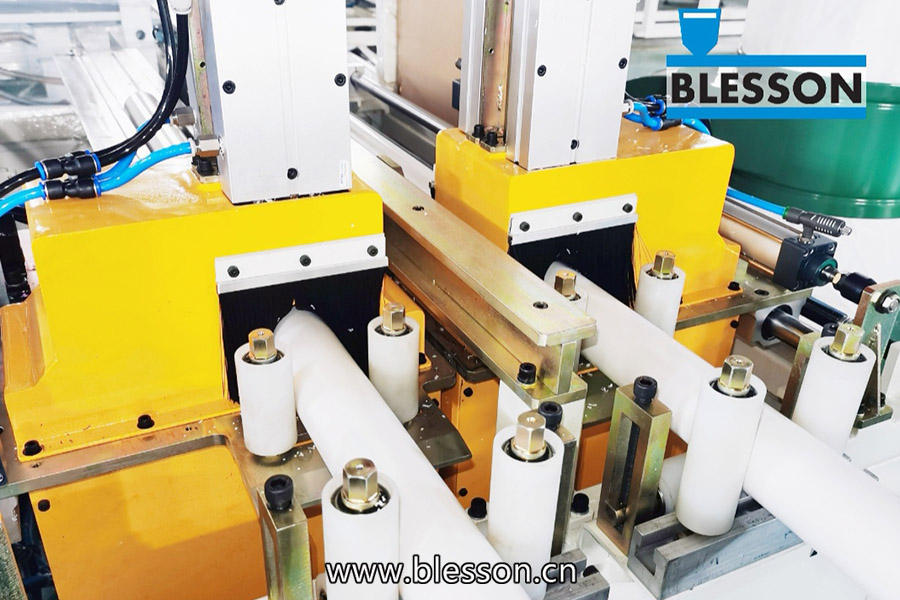

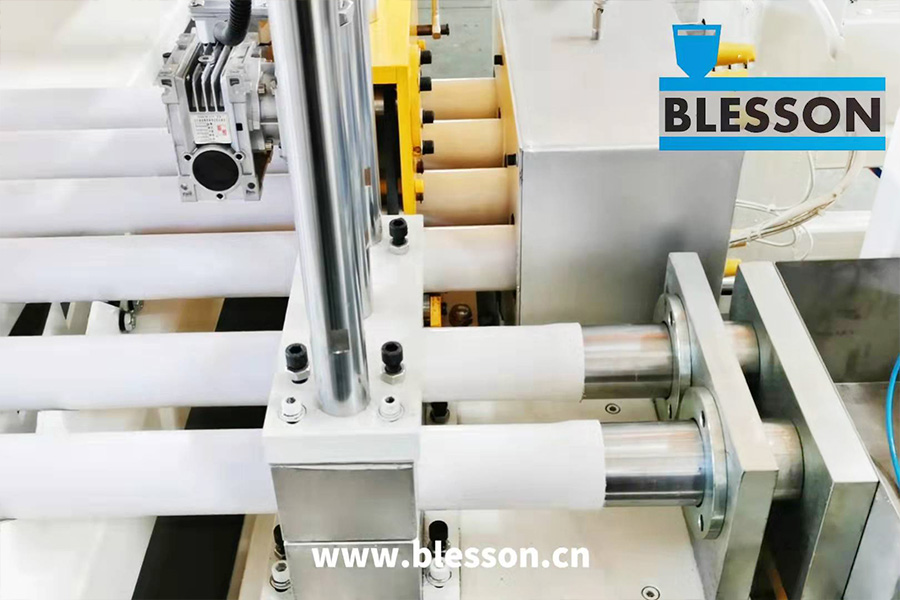

● Double Workstation Haul Off Unit of PVC Twin-Pipe Production Line:

1. According to the pipe diameter of PVC pipes, customers can choose double-belt haul-off unit or double-caterpillar haul-off unit.

2. Our double-belt haul-off unit is controlled by a permanent magnet synchronous motor with stable speed and low noise.

3. The upper caterpillar of our twin pipe double-station haul-off unit adopts pneumatic clamping method, while the lower one adopts electric synchronous lifting method. This design ensures that the caterpillar and the pipe maintain proper contact pressure, and improves the synchronization and stability of the haul-off unit.

4. The high-precision encoder can measure the length of the pipe in real time.

5. The rubber block of the caterpillar haul-off unit fixed by screw installation is firm and reliable and easy to disassemble for replacement.

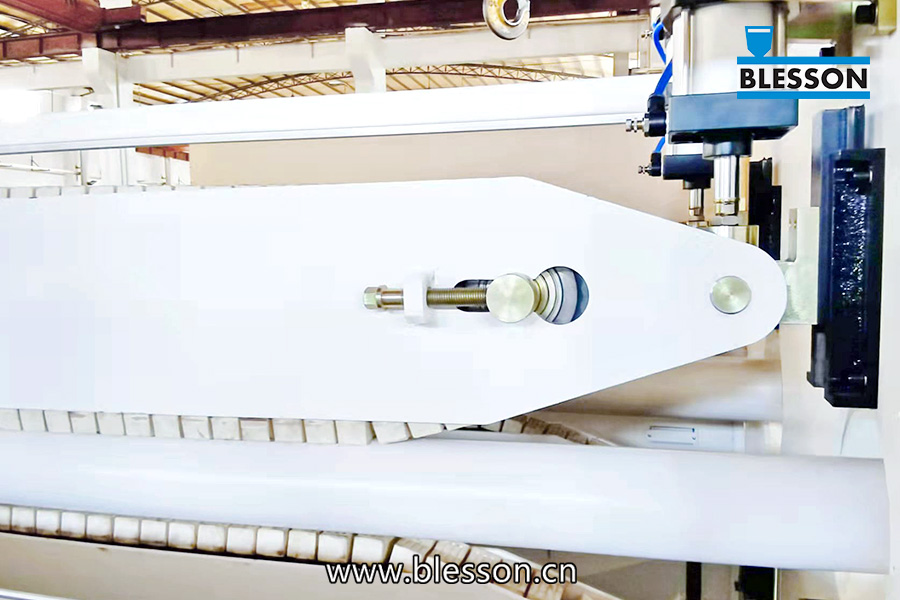

● Double Workstation Cutting Unit of Blesson PVC twin pipe production line:

1. According to different pipe diameters, our company can provide twin pipe double-station planetary cutting unit or double-station saw cutting unit.

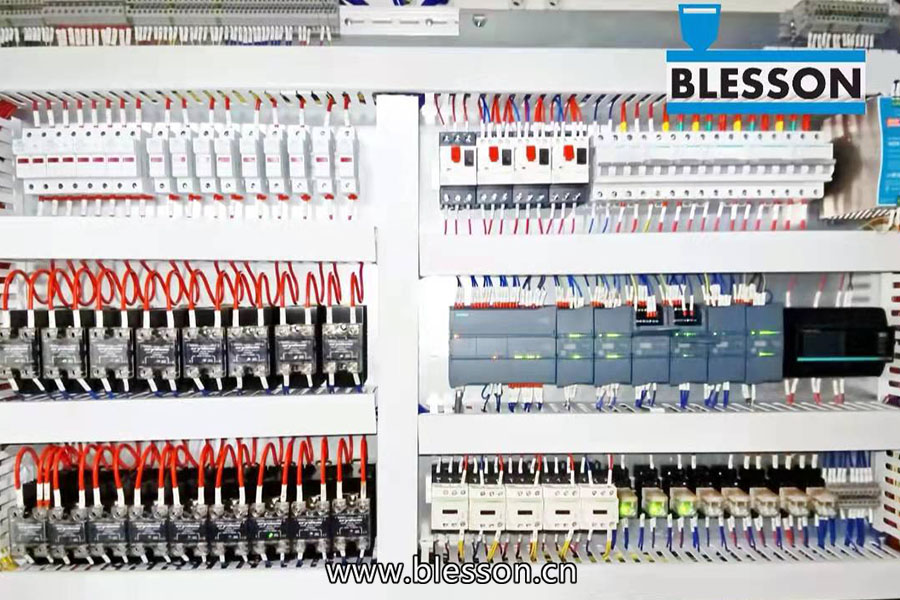

2. Our planetary cutting unit and double-station saw blade cutting unit are controlled by Siemens PLC touch screen, which is convenient to set the cutting mode. The cutting chambers are equipped with metal protection shelter to ensure the safety of the operator. With a powerful dust suction device, our cutter can effectively reduce the dust accumulated when cutting the pipe.

● Automatic socketing machine with four heating ovens & double socketing ovens for PVC twin-pipe production line:

1. Our company can customize fully automatic socketing machine according to the actual demand of various customers all over the world. Blesson fully automatic socketing machine adopts Siemens PLC control system and well-known electrical control components, with stable performance, safety and reliability.

2. The fully automatic socketing machine adopts both pneumatic or hydraulic ways of movement. With the automatic socket mold stripping after socketing, the socket pipes will be transferred into the stacker by the socketing machine.

3. The heating system of the fully automatic socketing machine adopts the rotary heating method to ensure that the pipe is heated evenly during the heating process. The cooling system can avoid the deformation of the pipe after heating and ensure the quality of the pipe.

Model list

|

PVC Twin-pipe Production Line |

|||||

|

Line Model |

Diameter Range(mm) |

Extruder Model |

Max. Output(kg/h) |

Length of Line(m) |

Total Installation Power(kw) |

|

BLS-63 PVC |

16-63 |

BLE65/132 |

280 |

26 |

125 |

|

BLS-63 PVC |

16-63 |

BLE65/132G |

450 |

26 |

115 |

|

BLS-110 PVC |

50-110 |

BLE80/156 |

450 |

28 |

200 |

|

BLS-160 PVC |

63-160 |

BLE92/188 |

850 |

40 |

320 |

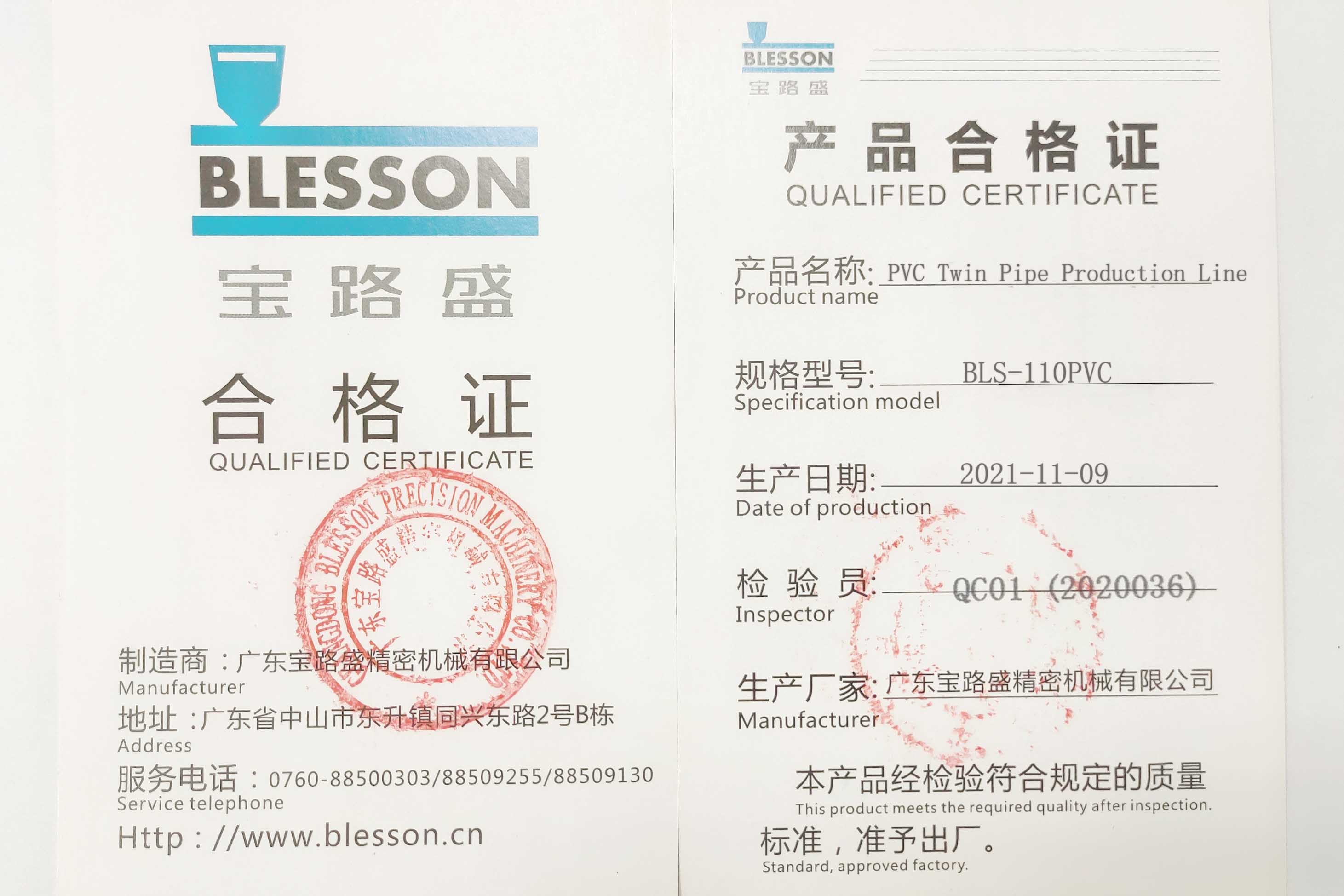

Warranty, Certificate Of Conformity

Guangdong Blesson Precision Machinery Co., Ltd. provides a one-year warranty service. During the use of the product, if you have any questions about the product, you can directly contact us for professional after-sales services.

Guangdong Blesson Precision Machinery Co., Ltd. provides product qualification certificates for each product sold, ensuring that each product has been inspected by professional technicians and debuggers.

Company Profile