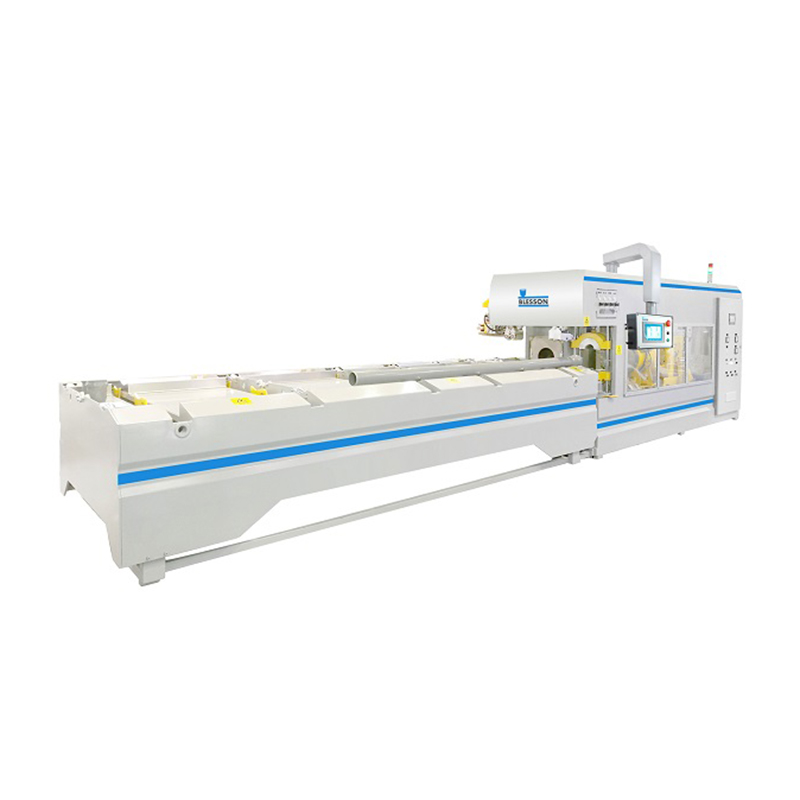

Automatic Socketing Machine For Plastic Pipe

Description

| Line Model | Pipe Range(mm) | Pipe Length(m) | Total Power(kW) | Socketing Type |

| BLK-40 five-pipe belling machine | 16-40 | 3-6 | 15 | U |

| BLK-63S twin-pipe belling machine | 16-63 | 3-6 | 8.4 | U |

| BLK-75 twin-pipe belling machine | 20-75 | 3-6 | 7 | U |

| BLK-110 single-pipe belling machine | 20-110 | 3-6 | 7 | U |

| BLK-110 twin-pipe belling machine | 32-110 | 3-6 | 15 | U/R |

| BLK-160 belling machine | 40-160 | 3-6 | 11 | U/R |

| BLK-250 belling machine | 50-250 | 3-6 | 14 | U/R |

| BLK-400 belling machine | 160-400 | 3-6 | 31 | U/R |

| BLK-630 belling machine | 250-630 | 4-8 | 40 | U/R |

| BLK-800 belling machine | 500-800 | 4-8 | 50 | R |

| BLK-1000 belling machine | 630-1000 | 4-8 | 60 | R |

Leave Your Message

Write your message here and send it to us